7-Oct-2023

NWH European electric wire rope hoist Uzbekistan

We can provide European style electric wire rope hoists for customers in Uzbekistan. The European style electric wire rope hoists adopt a C-type design, with a compact structure, smooth operation, and precise positioning. The efficient lifting and operating mechanism imported from Germany ensures that each electric hoist has excellent performance, safety and reliability. The application of new technologies such as frequency conversion control, brake energy feedback, and safety monitoring systems has always made Yuantai steel wire rope electric hoists at the forefront of the industry.

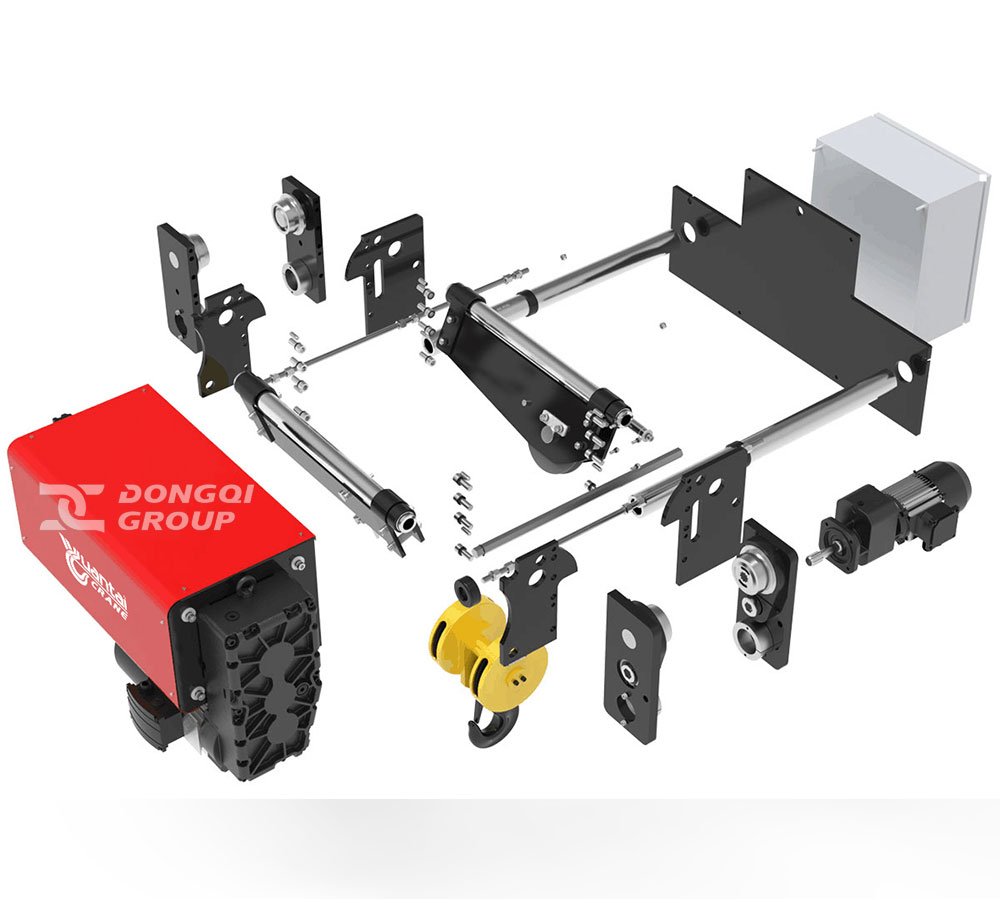

NWH European Electric Wire Rope Hoist Structure

Electric cabinet

Reasonable design, easy maintenance, a variety of security devices to ensure safe operation and running of equipment

Travelling system

Integrated design of gearbox, motor and brake, compact structure, stable operation, High efficiency ,small impact

Safety monitor

Novostar intelligent monitoring system, safe and practical, human-friendly interface, simple operation

Lifting motor

Aluminum shell, high- performance lifting motor with disc brakes, free maintenance design

Connectors

Connectors for aviation, safe and easy maintenance, high protection of IP55

Rope Guide

Made of engineering plastic, light weight, excellent wear resistance, reducing tear and wear of wire

Brake

Fast, highly reliable, automatic adjustment during braking interval, dust-proof, maintenance-free, Asbestos-free brake pads

Height limiter switch

Freely adjustable screw lifting height limiter with high precision and wide adjustment range ,Multi-touch configuration can effectively achieve the switch between fast and slow speed during rise and fall and stop function

Advantages of European style steel wire rope electric hoist products

- Extremely low wear and tear;

- Manufactured according to FEM level, with a long service life;

- Comply with international and domestic design standards;

- Having unique advantages to ensure safe, reliable, cost-effective operation, and value for money.

The steel wire rope drum adopts a deep groove design and is equipped with a high-strength steel wire rope guide mechanism as standard, ensuring a tighter and more regular rope arrangement, ensuring lifting safety and extending the service life of the steel wire rope.

The braking performance of high-strength DC disc brakes can reach twice the nominal torque, thereby implementing fast and active braking and locking functions.

Three stage transmission, involute helical gear, oil bath cast aluminum gearbox system. The precision machining gear group works in a leakage proof cast aluminum gearbox. The outer shell design of the transmission gear box is easy to dissipate heat through air, and is convenient for maintenance in the event of a malfunction. While ensuring maximum lifting capacity, it provides low clearance design specifications, saving you costs and improving usage efficiency. The lifting motor is a dual speed adjustable type, and the low speed ratio can be increased to 6:1, It can meet your comprehensive work requirements of accurate positioning for vulgar operation and fast takeoff and landing for high-speed operation.

The traction wheels made of alloy steel can be used on wide or even curved tracks, and the main engine is equipped with driving gears on both sides to provide more active driving guidance function.

All electrical control components adopt a safe IP54 protection level, and you can easily access the components you need to check when needed.

The high-strength metal bracket structure is safe and reliable, ensuring stable operation of the host.

The trolley mechanism can be easily adjusted to adapt to different track widths.

Within the high-end range, the upper and lower limit positions can be arbitrarily set to meet the widest range of usage requirements.

The lifting motor and trolley can be adjusted at two speeds for smooth acceleration and accurate load positioning.