7-Oct-2023

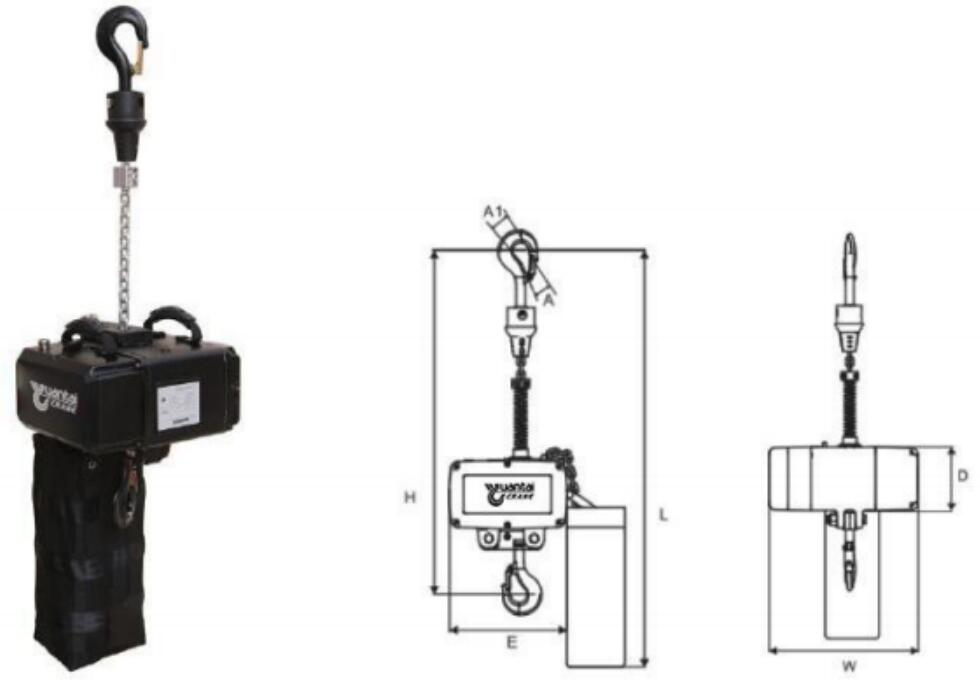

NCH Series Electric Chain Hoist Uzbekistan

NCH Series electric chain hoist are featured by compact structure and reliable performance. Chain hoists are designed and manufactured in strict compliance with FEM and DIN, while meeting standards and industry codes for special equipment of Chinese crane industry. The modular design allows flexible product mix for different lifting tonnage, speed and working level to meet customers’ individual needs.

The core driving components require no replacement within the safety utilization period (10 years). Standardized and personalized design improves operational performances while substantially reducing maintenance costs.

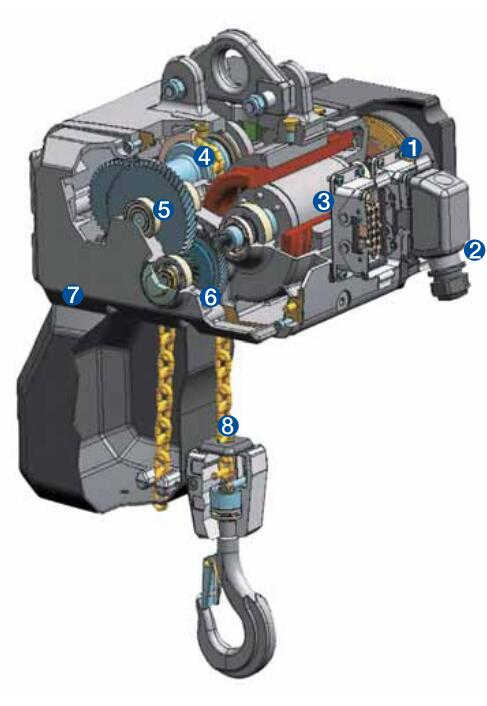

NCH Series Electric Chain Hoist Structure

1. Brake

Electromagnetic disc brake is integrated at the end of lifting motor with the brake torque of 2 times of rating of motor.

2. Electric connectors

Standard connectors of aluminum alloy are used as electrical interface, safe and convenient.

3. Lifting motor

Dual-speed motor with cylindrical rotor, reliable and low noise. Standard insulation class F, degrees of protection IP55

4. Chain fairlead

Chain fairlead is divided into two parts. The upper is made of engineering plastic and the lower of ductile iron.

5. Safety clutch

Safety clutch is integrated in the driving gear shaft, serving as an overload protection. Set and keep the torque 1.4 times of safe load.

6. Rotating mechanism

Three stage gear device with tooth surface of each gear hardened and ground, smooth running, low noise

7. Housing

Aluminum alloy shell, light weight, corrosion resistance and excellent heat dissipation

8. Chain

High-strength carburized chain, zinc plated, safe and durable.

Weights of electric chain hoist: NCH1=30Kg;NCH2=33Kg;NCH3=54Kg;NCH4=85Kg;NCH5=95Kg

Standard scope of supply of NCH series electric chain hoists includes:

- dual-speed hoist body, silver-gray finish; 2. removable lifting lug; 3. 380V/48V/50Hz lifting electronic control system; 4. manual electric switch for control of quick connector; 5. limit switch for rise and fall; 6. black chain box; 7. hook and chain (3 m lifting height)

A variety of options available for different applications.

1. 220V direct control; 2. manual or electric-operated trolley; 3. wireless remote controller; 4. extra-large chain box (higher lifting height)