27-Sep-2023

BCD1 Explosion-proof Wire Rope Electric Hoist Uzbekistan

HB (BCD) and HBS (BMD) explosion-proof electric hoists belong to a type of light and small lifting equipment. Commonly used tonnage includes: 0.5, 1, 2, 3, 5, 10, 16 tons (t), etc. It can be installed on explosion-proof single and double beam bridge cranes, gantry cranes, and cantilever cranes. With slight modifications, it can also be used as a winch. It is one of the commonly used lifting equipment in flammable and explosive, dust, water vapor, and corrosive workshops. It is an essential machinery to improve labor efficiency, improve labor conditions, and ensure the safe production of lifting in flammable and explosive workshops.

The design forms of HB (BCD) and HBS (BMD) explosion-proof electric hoists include trolley running type, trolley seat type, trolley hanging type, fixed seat type, fixed hanging type, etc. The manufacturer also provides design and manufacturing, installation and debugging, major overhaul and renovation, repair and maintenance, annual inspection and maintenance, and more explosion-proof/mining/marine electric hoists, metallurgical high-temperature resistance, acid cleaning, frequency conversion speed regulation, and other services in non-standard lifting stars, lifting height, lifting/operating speed, and changing control methods Please consult customer service for the brand, technical parameters, drawing design, construction plan, and quotation budget of national/non-standard/specialized electric hoist manufacturers such as high winch, twin (child mother type), European new low clearance, coaxial synchronization, etc.

Basic information

Explosion proof electric hoist is a specially designed material handling equipment with the features of explosion proof. Explosion proof electric hoist is designed and manufactured according to GB3836-2000 provisions and international regulations, with the explosion proof mark of D II BT4, and D II CT4, which can be supplied to applications that has the level of II A, II B, II C grade, the temperature sub-groups T1-T4 group of combustible gas, steam and air from the explosion gas mixtures in a zone, zone 2 areas. The lifting capacity of explosion proof electric hoist is 0.5 to 16 tons and working class of explosion proof hoist is M3. The main parameters of the hoist is as follow:

| Product Type | BCD |

|---|---|

| Lifting Capacity | 0.5~16t |

| Lifting Height | 6~18m |

| Working Class | M3 |

| Ambient Temperature | -25~40℃ |

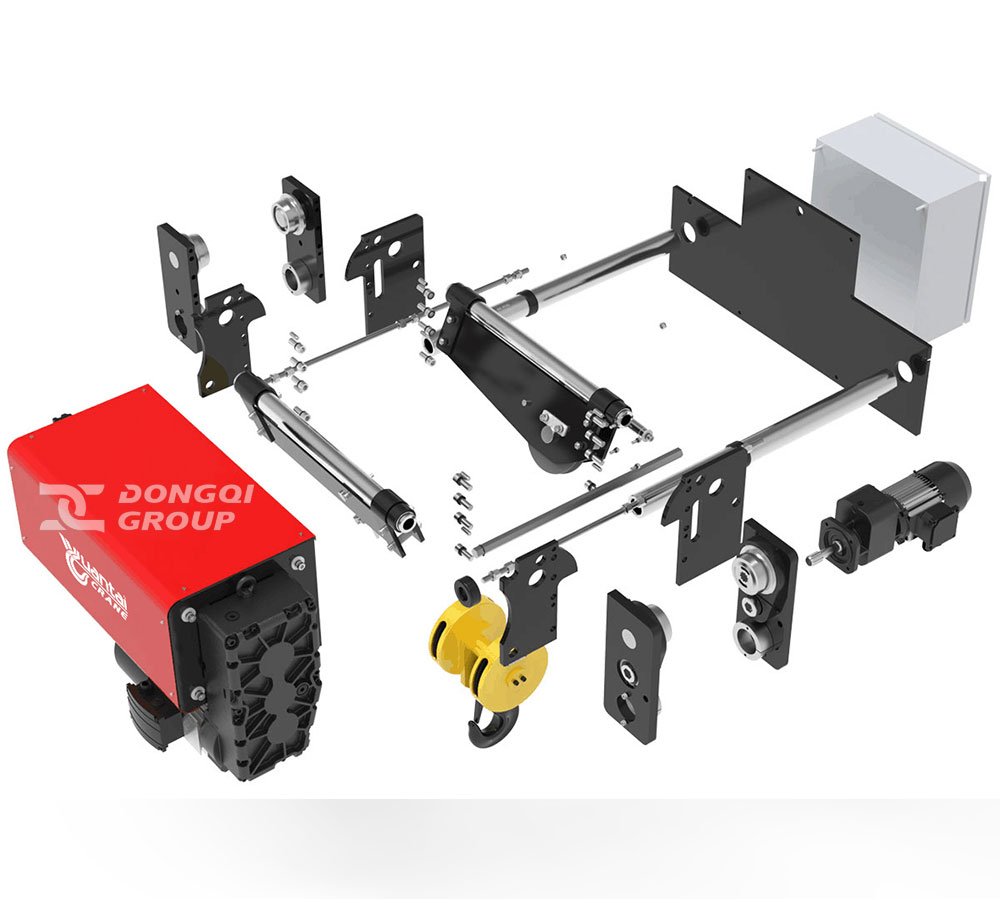

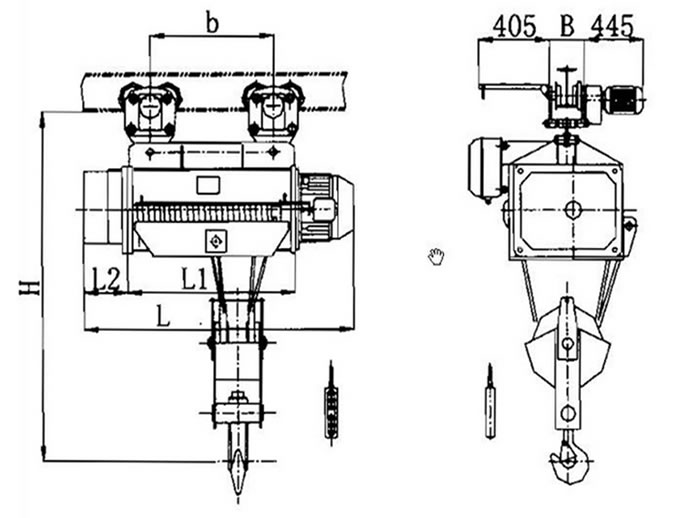

Design drawing

Advantages

Explosion proof electric hoist from Dongqi crane has the following advantages:

- Compact structure, small size, light weight, large capacity.

- High safety and reliability.

- All the spare parts are generalized and changeable, which make hoist maintenance easy and simple.

- No spark materials are used to the outside parts enhancing anti-explosion ability of electric hoist.

- Explosion proof electric hoist is designed and manufactured according to GB3836-2000.

Features

Explosion proof electric hoist from Dongqi crane has the following features:

1. On lifting motor

- Lifting motor used in explosion proof hoist is fully closed tapered rotor asynchronous motor of explosion-proof motor series.

- Max .torque of lifting motor is 2-3 times of full loading, ensuring the safety and reliability of explosion proof hoist.

- The lifting motor has the insulation class of B or F and the protection class is IP44/IP54.

2. Lifting reducer

- Explosion proof hoist adopts standardized modulus of cylindrical gears, installed with antifriction bearing, which is convenient to maintenance.

- High strength gear and gear shaft are made from heat treated alloy steel.

- Lifting reducer shell is made of high quality cast iron which is closely assembled and is dust proof.

- The lifting reducer can work reliably and high efficiency.

3. On hook

- The hook of explosion proof electric hoist is made of high quality carbon steel, supported in the hook beam through a single scroll thrust bearing, free oscillation.

- Hook for 5t and below loads is single slippery wheel whereas hook for 10t or heavier loads is double slide wheel.

- Explosion proof hoist use hooks with card board type structure at hook end.

- When explosion proof hoist is applied to application of explosion –proof dllCT4, the hood head will be made from stainless steel.

- Protection devices are adopted, such as, up and down traveling limiter, overloading limiter, and anti-clashing devices, etc.

4. Operation

Explosion proof electric hoist can be operated through wire rope control and remote control. The explosion proof switches is safe and reliable.