2-Nov-2023

RMG Crane Uzbekistan

We provide rail mounted container gantry cranes for our clients in Uzbekistan. Rail mounted container gantry cranes can be moved on fixed tracks and are suitable for large freight yards or docks that require frequent movement.

If you need to purchase a rail mounted container gantry crane, the main features of this gantry crane are as follows: the rail mounted container gantry crane can operate multiple containers simultaneously by installing multiple lifting tools, greatly improving work efficiency. When the span exceeds 40m, during the high-speed operation of the crane, there will be deviation due to different running resistance of the door legs on both sides. Therefore, a synchronization device is set up to maintain the synchronization of the running speed of the running mechanisms on both sides through the electrical control system. Rail mounted container gantry cranes are widely used in port freight yards due to their high site utilization, wide operating range, wide adaptability, and strong versatility, which are used in fixed locations. The disadvantage of rail mounted container gantry cranes is poor maneuverability.

The rail type container gantry crane is a specialized gantry crane with a lifting capacity of 50 tons (40.5 tons under the lifting appliance), working levels of A6~A7, 40 tons (35 tons under the lifting appliance), and working levels of A5~A6. It is mainly used for container loading, unloading, handling, and stacking work in railway, port, dock container transfer yards, and large container storage and transportation yards. It is composed of the main beam, rigid and flexible door legs, running trolley, lifting mechanism, rotating mechanism (optional: lifting tool rotation, upper trolley rotation, hook type), crane running mechanism, electrical system, operating cab, etc. 20 ‘, 40, 45’, and 40.5t electric telescopic lifting appliances can be selected for container gantry cranes, with intelligent control and remote control; Multiple anti swing devices and methods ensure safety and accuracy during the lifting process, improving work efficiency; The design, manufacturing, and testing of the crane comply with the provisions of GBT 19683-2005 “Rail mounted Container Gantry Cranes”.

According to the yard operation process, extending the cantilever in the direction of a single or double door leg becomes a single or double cantilever model, and not extending becomes a non cantilever model. Different structural forms of non cantilever, single cantilever, and double cantilever are determined based on the site, container storage and transportation process, and loading and unloading vehicles (container trucks or railway vehicles).

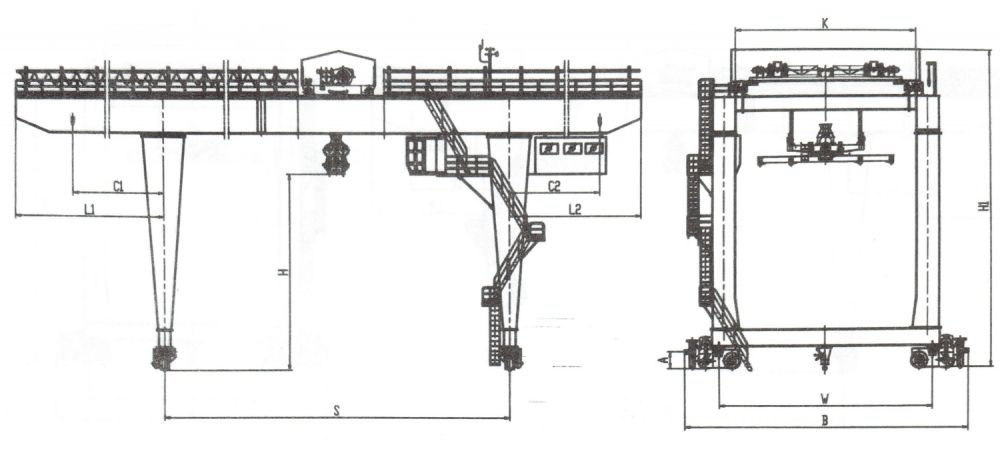

Outline Dimensional Drawing of 50 Ton Rail Container Gantry Crane

50-ton rail-mounted container gantry crane technical parameters and main dimensions data sheet

| Lifting capacity | t | 50 (40.5t under spreader) | |||

| Span(S) | mm | 26000 | 30000 | 35000 | |

| Lifting height(H) | 10000 | ||||

| work system | A6-A7 | ||||

| speed | Rise | m/min | Fully loaded 1.2-12 Unloaded 1.2-18 | ||

| Lower trolley operation | Fully loaded 4-40 Unloaded 4-60 | ||||

| Upper trolley operation | 1.5r/min | ||||

| Cart running | Fully loaded 4-40 Unloaded 4-60 | ||||

| electric motor | Rise | KW | 2x55KW | ||

| Car running | 2×7.5KW | ||||

| Cart operation | 4x11KW | 4x15KW | |||

| Maximum wheel pressure | KN | 348 | 370 | 395 | |

| Number of wheels | 8 | ||||

| Recommended rails | QU80-QU100 | ||||

| power supply | Three-phase AC 50HZ 380V | ||||

| Main dimensions (mm) | K | 8100 | |||

| W | 9600 | ||||

| B | 12600 | ||||

| A | 950 | ||||

| H | 10000 | ||||

| H1 | 17000 | ||||

| L1 | 8500 | 10500 | 12000 | ||

| C1 | 5500 | 7500 | 9000 | ||

| L2 | 8500 | 10500 | 12000 | ||

| C2 | 5500 | 7500 | 9000 | ||