25-Sep-2023

MDG Type Single Girder Gantry Crane Uzbekistan

Dongqi Crane can provide MDG gantry cranes to customers in Uzbekistan. MDG gantry cranes are a single beam gantry crane with large clear space. Due to the L-shaped structure, they are lightweight and have a low overall height; Compact structure, saving more costs and other characteristics. Compared to other models of gantry cranes, it is a cost-effective gantry crane. The maximum lifting capacity is 50 tons.

MDG single beam gantry cranes mostly adopt box and truss structures, with a wide range of applications. They can handle various pieces of goods and loose materials, with a lifting capacity of less than 100 tons and a span of 4-39 meters. It also includes a semi gantry crane. It should be noted that the MDG single beam limiter is configured as a protective device, which can ensure that the lifting circuit is automatically cut off when the hook is lifted to its position.

Overview

Design and manufacture according to GB/T 14406 “General gantry crane”.

Mainly made up of bridge, trolley, crane traveling mechanism and electric system.

All the procedure are finished in the operating room.

Applies to the open warehouse or rail along for general handling and lifting work.

Also can equipped with many lifting device for special work.

Prohibited for lifting high temperature solution, flammable, explosive, corrosion, overloading, dust and other dangerous operations.

Applications

Single-girder gantry crane with hook is used in outdoor storage, or loading and transporting along the railway.

Order instruction:

It is constituted with girder, crane traveling mechanism, trolley, electric equipment. Bridge frame use box welding structure, the crane traveling mechanism drive separately . The whole equipment is operated in a cab. Crane conductive form are cable and slippery touch line, you can choose any you need. If you select this kind of crane you must finish an ordering formal table, and remark the min and max temperature in working place, and the power source.

Features

(1) In General

- The machine with novel structure, attractive appearance, advanced technology.

- Flexible operation, safe and reliable.

- The spare parts are standardization, generalization and serialization.

(2) Main Body

- Single girder, welded box beams, the camber line is according to national standard.

- Adopts high quality carbon steel, Q235B or Q345B.

- The end truck adopts 10.9 high strength bolt connection.

- The crane traveling mechanism adopts separated driving.

(3) Electric System

- Module control speed, micro-speed and double speed.

- Traveling and lifting smoothly.

- The power for trolley moving adopts flat cable, sliding smoothly.

(4) Protection Devices

- Preventing hook clashing the top.

- Circuit self-test protection device.

- Protecting the current lacking of any phase.

- Outdoor cranes are equipped with hoisting mechanism, electrical control box and rainproof devices.

- Anti-collision, sound and light alarm devices.

- Equipped with rail clamp.

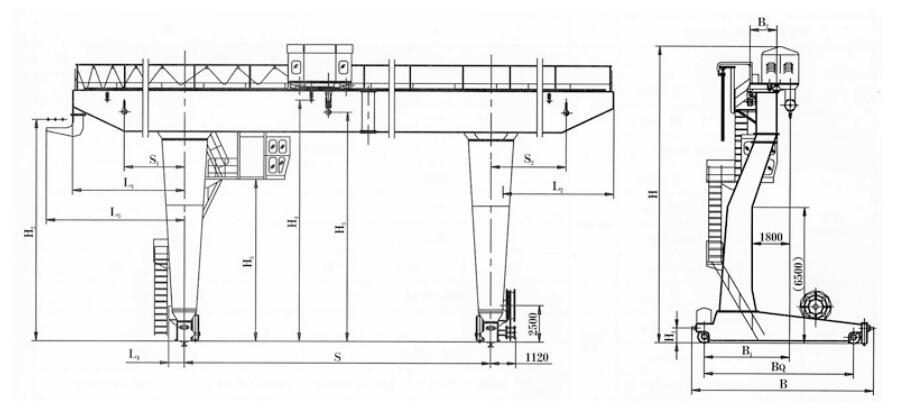

Drawing