26-Mar-2025

Gantry Lift Systems

In the world of material handling and industrial operations, gantry lift systems have emerged as a game-changer. These versatile and robust systems, often referred to simply as gantry lifts, are designed to handle heavy loads with precision and ease. Whether you’re looking for a gantry lift for sale for your workshop, warehouse, or construction site, this comprehensive guide will help you understand the features, benefits, and applications of gantry lift systems.

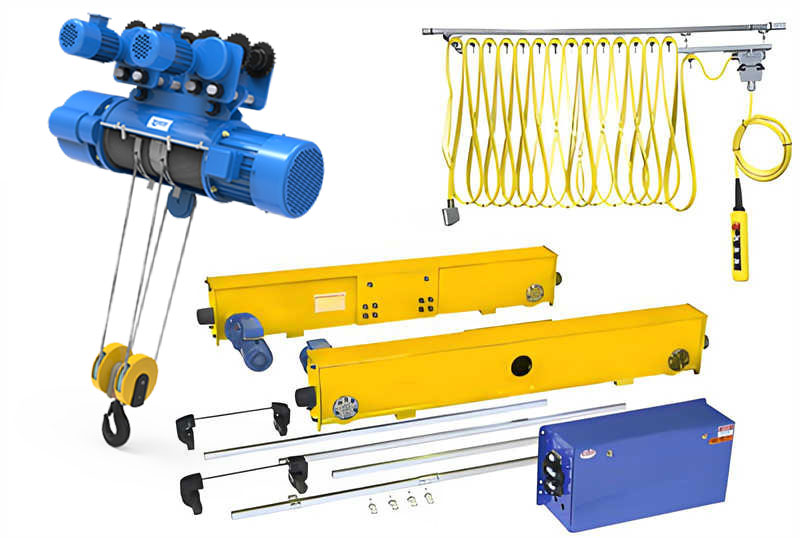

1. What is a Gantry Lift System?

A gantry lift system is a type of overhead lifting equipment that consists of a horizontal beam supported by two or more legs. These systems are typically equipped with a hoist or crane mechanism to lift and move heavy loads horizontally and vertically. Gantry lifts are widely used in industries such as manufacturing, construction, logistics, and automotive repair due to their versatility and efficiency.

Key Components of a Gantry Lift System

- Horizontal Beam: The main lifting arm that supports the hoist and load.

- Support Legs: Provide stability and can be fixed or adjustable in height.

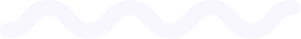

- Hoist Mechanism: The lifting device, which can be manual, electric, or pneumatic.

- Mobility Features: Wheels or casters for easy movement (in portable models).

2. Types of Gantry Lifts: A Detailed Overview

Gantry lifts are versatile lifting systems designed to meet a wide range of industrial and commercial needs. Depending on the application, load capacity, and workspace requirements, different types of gantry lifts are available. Below is a detailed overview of the most common types of gantry lifts, their features, and their ideal use cases.

2.1 Portable Gantry Lifts

Portable gantry lifts are lightweight, mobile lifting systems designed for easy transportation and assembly. They are ideal for applications where flexibility and mobility are essential.

Key Features:

- Lightweight Construction: Typically made from aluminium, these lifts are easy to move and set up.

- Adjustable Height and Width: Allows customization to fit different load sizes and workspace configurations.

- Mobility: Equipped with swivel casters or wheels for smooth movement across flat surfaces.

- Quick Assembly: Designed for easy setup and disassembly, making them perfect for temporary or on-site use.

Applications:

- Workshops and Garages: For lifting engines, transmissions, and other heavy components.

- Construction Sites: For moving building materials and equipment.

- Event Setup: For lifting and positioning stage equipment or lighting rigs.

Advantages:

- High portability and ease of use.

- Suitable for small spaces and temporary setups.

- Cost-effective solution for light to medium lifting tasks.

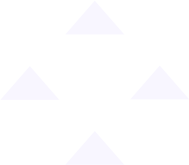

2.2 Fixed Gantry Lifts

Fixed gantry lifts are stationary systems designed for heavy-duty industrial applications. They are built to handle larger loads and provide maximum stability.

Key Features:

- Robust Construction: Made from steel for enhanced strength and durability.

- High Load Capacity: Can handle loads ranging from 5 tons to over 50 tons.

- Stable Base: Fixed legs provide a solid foundation for lifting heavy loads safely.

- Customizable Design: Can be tailored to fit specific workspace dimensions and load requirements.

Applications:

- Manufacturing Facilities: For assembling and transporting heavy machinery.

- Warehouses: For loading and unloading large goods.

- Shipyards: For lifting and positioning ship components.

Advantages:

- Exceptional stability and load-bearing capacity.

- Ideal for permanent installations in industrial settings.

- Low maintenance and long service life.

2.3 Adjustable Gantry Lifts

Adjustable gantry lifts are versatile systems that allow users to modify the height and width of the gantry to suit specific lifting tasks.

Key Features:

- Adjustable Legs and Beams: Enables customization for different load sizes and workspace layouts.

- Modular Design: Can be expanded or reconfigured as needed.

- Durable Materials: Available in both aluminium (for portability) and steel (for heavy-duty use).

- Compatibility: Works with various hoist types, including manual, electric, and pneumatic hoists.

Applications:

- Automotive Repair Shops: For lifting vehicles of different sizes.

- Construction Projects: For handling materials in varying workspace conditions.

- Maintenance Facilities: For servicing heavy equipment and machinery.

Advantages:

- High versatility and adaptability.

- Suitable for a wide range of lifting tasks.

- Reduces the need for multiple lifting systems.

2.4 A-Frame Gantry Lifts

A-frame gantry lifts feature a distinctive A-shaped structure, providing excellent stability and support for lifting heavy loads in confined spaces.

Key Features:

- Compact Design: Ideal for use in tight or restricted areas.

- Stable Structure: The A-frame design ensures balanced weight distribution and prevents tipping.

- Lightweight Options: Available in aluminium for easy portability.

- Heavy-Duty Options: Available in steel for industrial applications.

Applications:

- Small Workshops: For lifting engines, generators, and other heavy components.

- Construction Sites: For handling materials in confined spaces.

- Maintenance and Repair: For servicing machinery in limited-access areas.

Advantages:

- Excellent stability in confined spaces.

- Easy to assemble and disassemble.

- Suitable for both light and heavy lifting tasks.

Gantry lifts come in various types, each designed to meet specific lifting needs and workspace requirements. Whether you need a portable gantry lift for small-scale operations, a fixed gantry lift for heavy-duty industrial applications, or an adjustable gantry lift for versatile use, there’s a solution to suit your needs. By understanding the features, applications, and advantages of each type, you can choose the right gantry lift system to enhance efficiency, safety, and productivity in your operations.

When selecting a gantry lift, consider factors such as load capacity, portability, adjustability, and material to ensure you find the perfect fit for your requirements. With the right gantry lift system, you can streamline your material handling processes and achieve optimal results in your industry.

3. Benefits of Gantry Lift Systems

Gantry lift systems are highly versatile and efficient lifting solutions that offer numerous advantages across various industries. Their unique design and functionality make them indispensable for handling heavy loads safely and effectively. Below is a detailed exploration of the key benefits of gantry lift systems, highlighting how they enhance productivity, safety, and cost-efficiency in different applications.

3.1 Enhanced Safety

Safety is a top priority in any lifting operation, and gantry lift systems are designed with multiple features to ensure safe and reliable performance.

Key Safety Features:

- Overload Protection: Many gantry lifts are equipped with overload protection mechanisms that prevent the system from lifting loads beyond its rated capacity, reducing the risk of accidents.

- Stable Structure: The robust design of gantry lifts, especially fixed and A-frame models, provides excellent stability, minimizing the risk of tipping or collapsing during lifting operations.

- Secure Hoist Mechanisms: Gantry lifts are compatible with various hoist types (manual, electric, or pneumatic), all of which are designed to securely grip and lift heavy loads.

- Locking Casters: Portable gantry lifts often feature locking casters to ensure the system remains stationary during lifting, preventing unintended movement.

Benefits:

- Reduces the risk of workplace accidents and injuries.

- Ensures safe handling of heavy and bulky loads.

- Provides operators with confidence and peace of mind during lifting tasks.

3.2 Improved Efficiency and Productivity

Gantry lift systems streamline material handling processes, enabling faster and more efficient operations.

Key Efficiency Features:

- Quick Setup and Assembly: Portable and adjustable gantry lifts can be easily assembled and disassembled, saving time and effort.

- Versatility: Gantry lifts can handle a wide range of loads, from small components to heavy machinery, making them suitable for diverse applications.

- Precision Control: Electric and pneumatic hoists provide precise control over lifting and lowering operations, ensuring accurate positioning of loads.

- Mobility: Portable gantry lifts with wheels or casters can be easily moved around the workspace, reducing downtime and improving workflow.

Benefits:

- Speeds up material handling and lifting tasks.

- Reduces manual labor and physical strain on workers.

- Enhances overall productivity in industrial and commercial operations.

3.3 Cost-Effectiveness

Gantry lift systems offer a cost-effective solution for lifting and material handling needs.

Key Cost-Saving Features:

- Lower Installation Costs: Unlike fixed cranes, gantry lifts do not require permanent installation or structural modifications to the workspace.

- Reduced Maintenance: High-quality gantry lifts, especially those made from durable materials like aluminium or steel, require minimal maintenance and have a long service life.

- Energy Efficiency: Electric and pneumatic hoists consume less energy compared to traditional lifting methods, reducing operational costs.

- Multi-Purpose Use: A single gantry lift system can be used for various tasks, eliminating the need for multiple lifting devices.

Benefits:

- Lowers initial investment and operational costs.

- Provides a high return on investment (ROI) due to durability and versatility.

- Reduces long-term expenses by minimizing maintenance and energy consumption.

3.4 Space Efficiency

Gantry lifts are designed to maximize workspace efficiency, making them ideal for small or crowded environments.

Key Space-Saving Features:

- Compact Design: Portable and A-frame gantry lifts have a small footprint, allowing them to be used in tight spaces.

- Adjustable Dimensions: Adjustable gantry lifts can be customized to fit specific workspace requirements, optimizing available space.

- Easy Storage: Portable gantry lifts can be disassembled and stored when not in use, freeing up valuable floor space.

Benefits:

- Ideal for small workshops, garages, and warehouses.

- Maximizes usable workspace by minimizing equipment footprint.

- Enhances flexibility in workspace layout and organization.

3.5 Durability and Longevity

Gantry lift systems are built to withstand heavy use and harsh environments, ensuring long-term reliability.

Key Durability Features:

- High-Quality Materials: Gantry lifts are typically made from durable materials like aluminium (for lightweight portability) or steel (for heavy-duty applications).

- Corrosion Resistance: Aluminium gantry lifts are resistant to rust and corrosion, making them suitable for outdoor or humid environments.

- Robust Construction: Fixed and modular gantry lifts are designed to handle heavy loads and withstand rigorous use in industrial settings.

Benefits:

- Provides reliable performance over many years.

- Reduces the need for frequent replacements or repairs.

- Suitable for use in demanding environments, such as construction sites and shipyards.

3.6 Environmental Benefits

Gantry lift systems contribute to sustainability and environmental conservation in several ways.

Key Environmental Features:

- Energy Efficiency: Electric and pneumatic hoists consume less energy compared to traditional lifting methods, reducing carbon emissions.

- Recyclable Materials: Aluminium and steel gantry lifts are recyclable, minimizing waste and environmental impact.

- Reduced Fuel Consumption: Portable gantry lifts eliminate the need for fuel-powered lifting equipment, further reducing carbon footprints.

Benefits:

- Supports green initiatives and sustainability goals.

- Reduces operational costs through energy savings.

- Enhances the company’s reputation as an environmentally responsible organization.

3.7 Customization and Adaptability

Gantry lift systems can be customized to meet specific lifting requirements, making them highly adaptable to different industries and applications.

Key Customization Features:

- Adjustable Height and Width: Allows the system to handle loads of varying sizes and shapes.

- Modular Design: Modular gantry lifts can be expanded or reconfigured to suit changing needs.

- Compatibility with Accessories: Gantry lifts can be equipped with various hoists, beams, and legs to enhance functionality.

Benefits:

- Provides a tailored solution for unique lifting challenges.

- Adapts to evolving operational requirements.

- Reduces the need for multiple lifting systems, saving costs and space.

Gantry lift systems offer a wide range of benefits, from enhanced safety and efficiency to cost-effectiveness and environmental sustainability. Their versatility, durability, and adaptability make them indispensable tools in industries such as automotive repair, construction, warehousing, manufacturing, and more. By investing in a high-quality gantry lift system, businesses can improve productivity, reduce operational costs, and create a safer and more efficient work environment.

Whether you need a portable gantry lift for small-scale tasks or a heavy-duty gantry lift for industrial applications, these systems provide a reliable and cost-effective solution for all your lifting needs. With proper selection and maintenance, gantry lifts can significantly enhance your material handling processes and contribute to the success of your operations.

4. Applications of Gantry Lift Systems

Gantry lift systems are incredibly versatile and are used across a wide range of industries to handle heavy loads safely and efficiently. Their adaptability, portability, and robust design make them indispensable in various applications. Below is a detailed exploration of the key industries and scenarios where gantry lift systems are commonly used, along with specific examples of their applications.

4.1 Automotive Repair and Maintenance

Gantry lifts are widely used in automotive repair shops and maintenance facilities for lifting vehicles, engines, transmissions, and other heavy components.

Specific Applications:

- Engine Removal and Installation: Portable gantry lifts are ideal for lifting engines out of vehicles during repairs or replacements.

- Transmission Servicing: Adjustable gantry lifts provide the flexibility to handle transmissions of different sizes and weights.

- Vehicle Body Work: A-frame gantry lifts are used to lift car bodies for undercarriage repairs or modifications.

- Tire and Brake Maintenance: Lightweight gantry lifts make it easy to lift vehicles for tire changes or brake inspections.

Benefits:

- Improves efficiency and safety in automotive repair tasks.

- Reduces physical strain on workers by providing mechanical lifting assistance.

- Portable models allow for easy movement around the workshop.

4.2 Construction and Building Sites

In the construction industry, gantry lifts are essential for moving heavy building materials, equipment, and machinery.

Specific Applications:

- Material Handling: Fixed gantry lifts are used to lift and transport steel beams, concrete blocks, and other construction materials.

- Equipment Installation: Modular gantry lifts assist in positioning heavy machinery like generators, HVAC systems, and industrial equipment.

- Scaffolding Assembly: Portable gantry lifts help in lifting and assembling scaffolding components safely.

- Bridge and Road Construction: Heavy-duty gantry lifts are used to handle large prefabricated sections of bridges and roads.

Benefits:

- Enhances productivity by streamlining material handling processes.

- Reduces the risk of accidents and injuries on construction sites.

- Provides stability and precision when lifting heavy loads.

4.3 Warehousing and Logistics

Gantry lifts play a crucial role in warehouses and logistics centers for loading, unloading, and organizing heavy goods.

Specific Applications:

- Loading and Unloading: Portable gantry lifts are used to load and unload heavy cargo from trucks and containers.

- Pallet Handling: Adjustable gantry lifts assist in moving and stacking pallets of goods.

- Inventory Management: Fixed gantry lifts are used to lift and store heavy items in high racks.

- Order Fulfillment: Lightweight gantry lifts help in picking and packing heavy items for shipping.

Benefits:

- Improves efficiency in warehouse operations.

- Reduces manual labor and the risk of workplace injuries.

- Ensures safe handling of heavy and bulky items.

4.4 Manufacturing and Industrial Facilities

In manufacturing plants, gantry lifts are used for assembling, transporting, and maintaining heavy machinery and equipment.

Specific Applications:

- Machinery Assembly: Modular gantry lifts are used to position and assemble large industrial machines.

- Production Line Support: Fixed gantry lifts assist in moving heavy components along the production line.

- Maintenance and Repair: Adjustable gantry lifts provide access to machinery for servicing and repairs.

- Tool and Die Handling: A-frame gantry lifts are used to lift and position heavy tools and dies in manufacturing processes.

Benefits:

- Enhances precision and efficiency in manufacturing processes.

- Reduces downtime by facilitating quick and safe equipment maintenance.

- Provides a reliable solution for handling heavy loads in industrial settings.

4.5 Shipbuilding and Marine Industry

Gantry lifts are essential in shipyards and marine facilities for lifting and positioning heavy ship components.

Specific Applications:

- Ship Assembly: Heavy-duty gantry lifts are used to lift and position large sections of ships during assembly.

- Engine Installation: Fixed gantry lifts assist in installing ship engines and propulsion systems.

- Maintenance and Repair: Portable gantry lifts provide access to ship hulls and engines for maintenance work.

- Cargo Handling: Adjustable gantry lifts are used to load and unload heavy cargo from ships.

Benefits:

- Ensures safe and efficient handling of heavy ship components.

- Reduces the risk of accidents in shipbuilding and repair operations.

- Provides stability and precision in lifting tasks.

4.6 Aerospace Industry

In the aerospace industry, gantry lifts are used for assembling and transporting aircraft components.

Specific Applications:

- Aircraft Assembly: Modular gantry lifts are used to position and assemble large sections of aircraft.

- Engine Installation: Fixed gantry lifts assist in installing aircraft engines.

- Maintenance and Repair: Adjustable gantry lifts provide access to aircraft for servicing and repairs.

- Component Handling: Lightweight gantry lifts are used to move and position smaller aircraft components.

Benefits:

- Enhances precision and safety in aircraft assembly and maintenance.

- Reduces the risk of damage to expensive aircraft components.

- Provides a reliable solution for handling heavy and delicate parts.

4.7 Event Management and Entertainment Industry

Gantry lifts are used in the event management and entertainment industry for setting up stages, lighting, and sound equipment.

Specific Applications:

- Stage Setup: Portable gantry lifts are used to lift and position stage components, lighting rigs, and sound equipment.

- Lighting and Sound Installation: Adjustable gantry lifts provide access to high areas for installing lighting and sound systems.

- Equipment Transport: Lightweight gantry lifts assist in moving heavy equipment around event venues.

- Temporary Structures: Modular gantry lifts are used to assemble and disassemble temporary structures like stages and platforms.

Benefits:

- Improves efficiency in event setup and teardown.

- Reduces the risk of accidents during equipment installation.

- Provides a versatile solution for handling heavy equipment in event venues.

4.8 Mining and Heavy Industries

In mining and heavy industries, gantry lifts are used for handling heavy machinery, equipment, and materials.

Specific Applications:

- Equipment Maintenance: Fixed gantry lifts provide access to heavy machinery for servicing and repairs.

- Material Handling: Portable gantry lifts assist in moving heavy materials like ore and equipment in mining operations.

- Component Assembly: Modular gantry lifts are used to assemble large components of mining machinery.

- Transportation: Adjustable gantry lifts help in loading and unloading heavy equipment from trucks and trains.

Benefits:

- Enhances safety and efficiency in mining operations.

- Reduces downtime by facilitating quick equipment maintenance.

- Provides a reliable solution for handling heavy loads in harsh environments.

Gantry lift systems are indispensable tools across a wide range of industries, from automotive repair and construction to aerospace and event management. Their versatility, portability, and robust design make them ideal for handling heavy loads safely and efficiently. By understanding the specific applications and benefits of gantry lifts in different industries, businesses can choose the right system to enhance productivity, safety, and operational efficiency.

Whether you need a portable gantry lift for small-scale tasks or a heavy-duty gantry lift for industrial applications, these systems offer a reliable and cost-effective solution for all your lifting needs. With proper selection and maintenance, gantry lifts can significantly improve your material handling processes and contribute to the success of your operations.

5. Key Features to Look for in a Gantry Lift for Sale

When searching for a gantry lift for sale, consider the following features to ensure you choose the right system for your needs:

5.1 Load Capacity

Ensure the gantry lift can handle your maximum load requirements.

5.2 Adjustability

Look for systems with adjustable height and width for versatility.

5.3 Mobility

If portability is important, choose a model with wheels or casters.

5.4 Material

Aluminium gantry lifts are lightweight and corrosion-resistant, while steel models offer greater strength.

5.5 Safety Features

Check for features like locking casters, overload protection, and secure hoist mechanisms.

6. Comparison of Popular Gantry Lift Models

To help you make an informed decision, here’s a comparison of popular gantry lift models:

| Model | Load Capacity | Material | Adjustable Height | Portability | Price Range |

|---|---|---|---|---|---|

| Portable Gantry A | 1 Ton | Aluminium | Yes | High | $500 – $800 |

| Fixed Gantry B | 5 Tons | Steel | No | Low | $1,500 – $2,500 |

| Adjustable Gantry C | 2 Tons | Steel/Aluminium | Yes | Medium | $700 – $1,000 |

| A-Frame Gantry D | 0.5 Ton | Aluminium | Yes | High | $400 – $600 |

7. Maintenance Tips for Gantry Lift Systems

To ensure the longevity and optimal performance of your gantry lift system, follow these maintenance tips:

- Regular Inspections: Check for wear and tear, especially on hoist mechanisms and casters.

- Lubrication: Keep moving parts well-lubricated to prevent friction and damage.

- Cleaning: Remove dirt and debris to avoid corrosion and ensure smooth operation.

- Storage: Store in a dry, covered area to protect from environmental damage.

8. Where to Buy a Gantry Lift for Sale

When searching for a gantry lift for sale, it’s crucial to choose a trusted and reputable supplier. Dongqi Crane stands out as a leading manufacturer and provider of high-quality gantry lift systems, offering a wide range of products tailored to meet diverse industrial needs. Here’s why Dongqi Crane should be your go-to choice for purchasing a gantry lift:

8.1 Why Choose Dongqi Crane?

- Proven Expertise: With years of experience in the crane and lifting equipment industry, Dongqi Crane has built a reputation for delivering reliable and innovative solutions.

- High-Quality Products: Dongqi Crane’s gantry lifts are manufactured using premium materials, ensuring durability, stability, and long-term performance.

- Customization Options: Whether you need a portable gantry lift, a fixed gantry lift, or an adjustable gantry lift, Dongqi Crane offers customizable solutions to meet your specific requirements.

- Global Reach: Dongqi Crane serves customers worldwide, providing efficient logistics and timely delivery.

8.2 Product Range

Dongqi Crane offers a comprehensive range of gantry lift systems, including:

- Portable Gantry Lifts: Lightweight and easy to move, ideal for workshops and small-scale operations.

- Fixed Gantry Lifts: Robust and stable, designed for heavy-duty industrial applications.

- Adjustable Gantry Lifts: Customizable height and width for versatile use.

- A-Frame Gantry Lifts: Compact and stable, perfect for confined spaces.

8.3 Customer Support and Services

- Professional Consultation: Dongqi Crane’s team of experts provides personalized guidance to help you select the right gantry lift for your needs.

- Installation and Training: Comprehensive support for installation and operator training ensures safe and efficient use of the equipment.

- After-Sales Service: Dongqi Crane offers reliable maintenance and repair services to keep your gantry lift in optimal condition.

8.4 Warranty and Quality Assurance

Dongqi Crane stands behind the quality of its products with robust warranties and rigorous quality control processes. Each gantry lift undergoes thorough testing to ensure it meets international standards and customer expectations.

8.5 How to Purchase

To explore Dongqi Crane’s range of gantry lifts and find the perfect gantry lift for sale, visit their official website or contact their sales team directly. With Dongqi Crane, you can expect a seamless purchasing experience, from product selection to delivery and beyond.

By choosing Dongqi Crane, you’re not just buying a gantry lift – you’re investing in a reliable, high-performance solution backed by industry expertise and exceptional customer service. Whether you’re looking for a portable, fixed, or adjustable gantry lift, Dongqi Crane has the right product to meet your needs. Visit Dongqi Crane today and take the first step toward enhancing your material handling operations with a top-quality gantry lift system.

9. Conclusion

Gantry lift systems are essential tools for modern material handling, offering versatility, portability, and safety. Whether you need a portable gantry lift for small-scale operations or a robust fixed gantry lift for industrial applications, understanding the features and benefits of these systems will help you make the right choice.

By comparing different models and considering factors like load capacity, adjustability, and portability, you can find the perfect gantry lift for sale to meet your needs. With proper maintenance and care, these lifting systems will provide reliable performance for years to come, enhancing efficiency and safety in your operations.