2-Apr-2025

3 Ton Overhead Crane

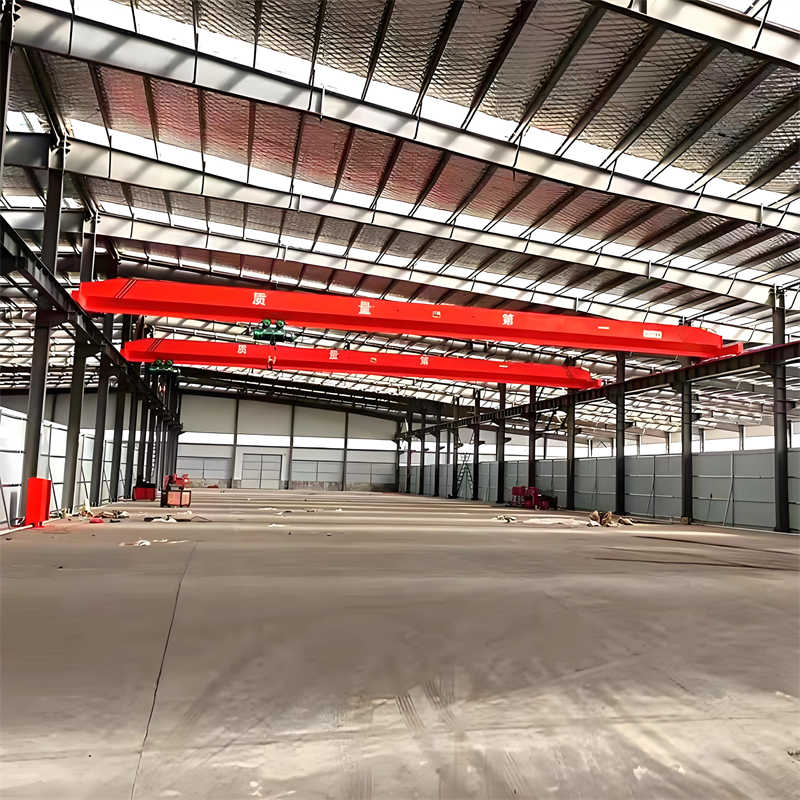

When it comes to material handling in industrial settings, 3 ton overhead cranes offer the perfect balance of power and precision for medium-duty applications. As a leading manufacturer, Dongqi Crane provides high-quality 3 ton bridge crane solutions that combine reliability, efficiency, and competitive pricing. This comprehensive guide explores everything you need to know about 3 ton overhead cranes, including their features, benefits, pricing considerations, and how they compare to other capacity options.

Understanding 3 Ton Overhead Cranes

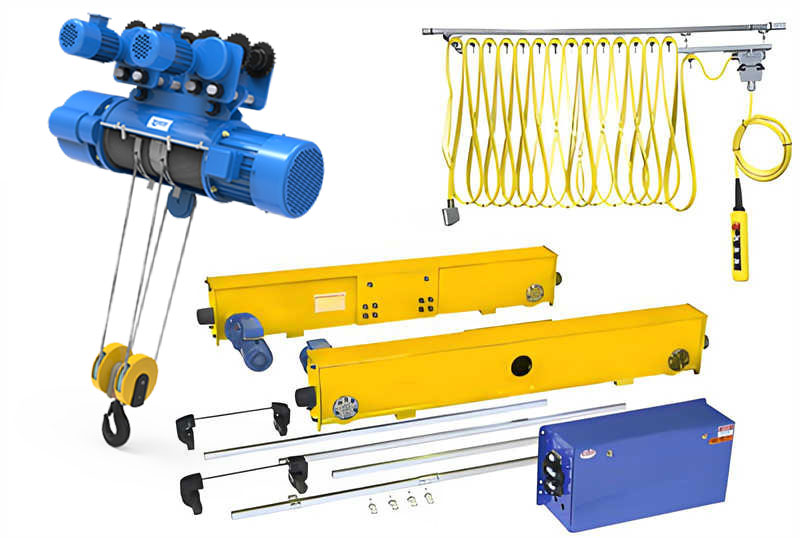

A 3 ton overhead crane, also known as a 3 ton bridge crane, is a material handling system that consists of parallel runways with a traveling bridge spanning the gap. The hoist, which can lift up to 3 tons (6,000 lbs), moves along the bridge to position loads anywhere within the crane’s working area.

Key Features of Dongqi’s 3 Ton Overhead Cranes:

- Lifting Capacity: 3 metric tons (3,000 kg)

- Span Options: Customizable from 5 meters to 30+ meters

- Lifting Height: Standard 6 meters, adjustable as needed

- Operation Modes: Manual, pendant control, or radio remote control

- Duty Class: Typically FEM 1Am to FEM 2m for general industrial use

- Safety Features: Overload protection, limit switches, emergency stop

Comparing 3 Ton Cranes to Other Capacities

When selecting an overhead crane, it’s important to choose the right capacity for your needs. Here’s how 3 ton cranes compare to other options:

| Capacity | Best For | Advantages | Limitations |

|---|---|---|---|

| 1-2 Ton | Light assembly, maintenance | Lower cost, simpler installation | Limited heavy-duty capability |

| 3 Ton | General manufacturing, warehouses | Versatile for medium loads, cost-effective | Not for heavy industrial use |

| 5-10 Ton | Heavy parts, steel service | Higher capacity, robust construction | Higher price, more structural support needed |

| 15+ Ton | Foundries, heavy industry | Extreme capacity, specialized designs | Significant infrastructure requirements |

The 3 ton overhead crane hits the sweet spot for many operations, offering substantial lifting power without the excessive costs associated with higher-capacity models. For businesses that occasionally handle loads between 1-3 tons, this capacity provides necessary headroom without over-investing.

3 Ton Overhead Crane Price Considerations

The 3 ton overhead crane price varies depending on several factors:

- Type of Crane:

- Single girder (more economical, ~$8,000-$25,000)

- Double girder (higher capacity headroom, ~$20,000-$50,000)

- Control System:

- Manual chain hoist ($8,000-$15,000)

- Electric pendant control (+$2,000-$5,000)

- Radio remote system (+$3,000-$7,000)

- Span Length:

- Longer spans require heavier beams and supports, increasing costs by $1,000-$3,000 per additional meter

- Installation Requirements:

- Freestanding vs. building-supported

- Electrical work and commissioning

- Additional Features:

- Frequency control for smoother operation

- Special environmental protections (heat, dust, corrosion)

- Custom paint colors or finishes

Dongqi Crane offers competitive pricing by manufacturing cranes directly without middlemen, passing the savings to customers. While exact 3 ton overhead crane for sale prices require customized quotes, our solutions typically offer 15-30% better value than comparable Western brands without sacrificing quality.

Why Choose Dongqi’s 3 Ton Bridge Crane?

- Proven Reliability: Our cranes undergo rigorous testing with 125% load testing before delivery.

- Energy Efficient: Modern motor designs reduce power consumption by up to 30% compared to conventional models.

- Low Maintenance: Sealed bearings, durable wire ropes, and high-quality electrical components minimize downtime.

- Custom Solutions: We can adapt our standard 3 ton design for:

- High-temperature environments (up to 60°C)

- Corrosive atmospheres (marine coatings)

- Clean room applications (special finishes)

- Explosion-proof requirements

- Complete Service Package:

- Professional installation supervision

- Operator training programs

- After-sales support with readily available spare parts

Applications for 3 Ton Overhead Cranes – Detailed Industry Uses

A 3 ton overhead crane is a versatile lifting solution suitable for various industries due to its optimal balance between capacity, cost, and efficiency. Below is a detailed breakdown of its applications across different sectors:

1. Manufacturing & Assembly Lines

- Machine Part Handling: Moving heavy components (engine blocks, gearboxes, hydraulic systems) during assembly.

- Production Line Support: Transporting raw materials (steel plates, aluminum bars) to workstations.

- Tool Positioning: Assisting in the precise placement of large molds, dies, and fixtures.

- Automated Integration: Can be combined with robotic arms for automated production processes.

2. Warehousing & Logistics

- Pallet & Container Handling: Loading/unloading goods (3-ton pallets, crates, and packaged materials).

- Truck Loading/Unloading: Efficiently moving heavy shipments in and out of transport vehicles.

- Storage Management: Positioning bulky inventory in high-bay warehouses.

- Cross-Docking Operations: Transferring goods between trucks without intermediate storage.

3. Automotive & Aerospace Industries

- Engine & Transmission Installation: Lifting and positioning heavy powertrain components.

- Chassis & Body Assembly: Moving vehicle frames and large body panels.

- Aircraft Component Handling: Assisting in the assembly of smaller aircraft parts (landing gear, wing sections).

- Battery Handling (EV Manufacturing): Transporting heavy electric vehicle battery packs.

4. Metalworking & Steel Fabrication

- Steel Plate & Beam Handling: Moving and positioning metal sheets (up to 3 tons) for cutting and welding.

- Coil & Pipe Transport: Lifting and transferring steel coils, pipes, and structural beams.

- CNC Machine Feeding: Loading raw materials into laser cutters, presses, and machining centers.

- Foundry Operations: Handling castings, molds, and furnace charges in metal processing plants.

5. Construction & Building Material Handling

- Precast Concrete Movement: Transporting prefabricated concrete slabs, columns, and beams.

- Rebar & Structural Steel Handling: Assisting in the assembly of steel frameworks.

- Glass & Panel Installation: Safely lifting large glass panes or facade panels during construction.

6. Maintenance & Repair Workshops

- Industrial Equipment Servicing: Removing heavy motors, pumps, and gearboxes for maintenance.

- Vehicle Repair (Trucks, Buses, Heavy Machinery): Hoisting engines, transmissions, and axles.

- Power Plant & Facility Maintenance: Assisting in the replacement of turbines, generators, and large valves.

7. Paper & Printing Industry

- Paper Roll Handling: Transporting large paper rolls (up to 3 tons) in printing and packaging facilities.

- Machinery Maintenance: Lifting heavy rollers and press components for servicing.

8. Energy & Renewable Sector

- Wind Turbine Component Handling: Assisting in the assembly of smaller turbine parts (gearboxes, generators).

- Solar Panel Installation: Moving heavy solar arrays and mounting structures.

- Power Substation Maintenance: Lifting transformers and switchgear components.

9. Food & Beverage Processing

- Bulk Ingredient Handling: Moving large sacks of raw materials (sugar, flour, grains).

- Equipment Maintenance: Lifting mixers, vats, and processing machinery for cleaning/repair.

10. Shipbuilding & Marine Applications

- Small Boat Assembly: Handling engines, hull sections, and deck components.

- Dockyard Maintenance: Assisting in the repair of marine equipment and machinery.

Why Choose a 3 Ton Overhead Crane for These Applications?

✔ Cost-Effective – More affordable than higher-capacity cranes while still handling substantial loads.

✔ Space-Efficient – Ideal for medium-sized workshops and factories without requiring massive structural reinforcement.

✔ Versatile – Can be configured with different hoists (chain, wire rope) and controls (pendant, remote).

✔ Safety & Precision – Ensures controlled lifting, reducing manual handling risks.

Purchasing Your 3 Ton Overhead Crane

When considering a 3 ton overhead crane for sale, follow these steps:

- Assess Your Needs:

- Maximum weight including rigging

- Required span and height

- Duty cycle (how frequently it will operate)

- Prepare Your Facility:

- Verify building structural capacity

- Ensure adequate clearance

- Plan electrical supply routes

- Request a Quote:

- Provide facility drawings

- Specify operational requirements

- Identify any special conditions

- Compare Options:

- Single vs. double girder

- Control preferences

- Warranty terms (Dongqi offers 18 months standard)

- Plan for Installation:

- Schedule during production downtime if possible

- Prepare operator training

Maintenance Tips for Long Service Life

To maximize your investment in a 3 ton bridge crane:

- Daily Checks:

- Visual inspection of hooks, wires, and brakes

- Listen for unusual noises during operation

- Monthly Maintenance:

- Lubricate all moving parts

- Check electrical connections

- Test safety devices

- Annual Service:

- Professional inspection by Dongqi technicians

- Load testing verification

- Structural integrity assessment

Future-Proofing Your Investment

Dongqi’s 3 ton cranes are designed with adaptability in mind:

- Capacity Upgrades: Many models can be upgraded to 5 tons with minor modifications

- Technology Integration: Compatible with IoT monitoring systems

- Expansion Ready: Modular designs allow for extending runway systems

Conclusion

A 3 ton overhead crane from Dongqi Crane represents an optimal solution for businesses needing reliable, medium-capacity material handling. With competitive 3 ton overhead crane price points and versatile configurations available for sale, these cranes deliver exceptional value. Whether you’re comparing capacities, evaluating different control systems, or planning your facility layout, our engineering team can help you select and customize the perfect 3 ton bridge crane solution for your specific requirements.

For more information on our 3 ton overhead crane products or to request a customized quote, contact Dongqi Crane today. Our experts will guide you through the selection process to ensure you get the ideal lifting solution that maximizes your productivity and return on investment.