27-Sep-2023

CD1/MD1 Electric Wire Rope Hoist Uzbekistan

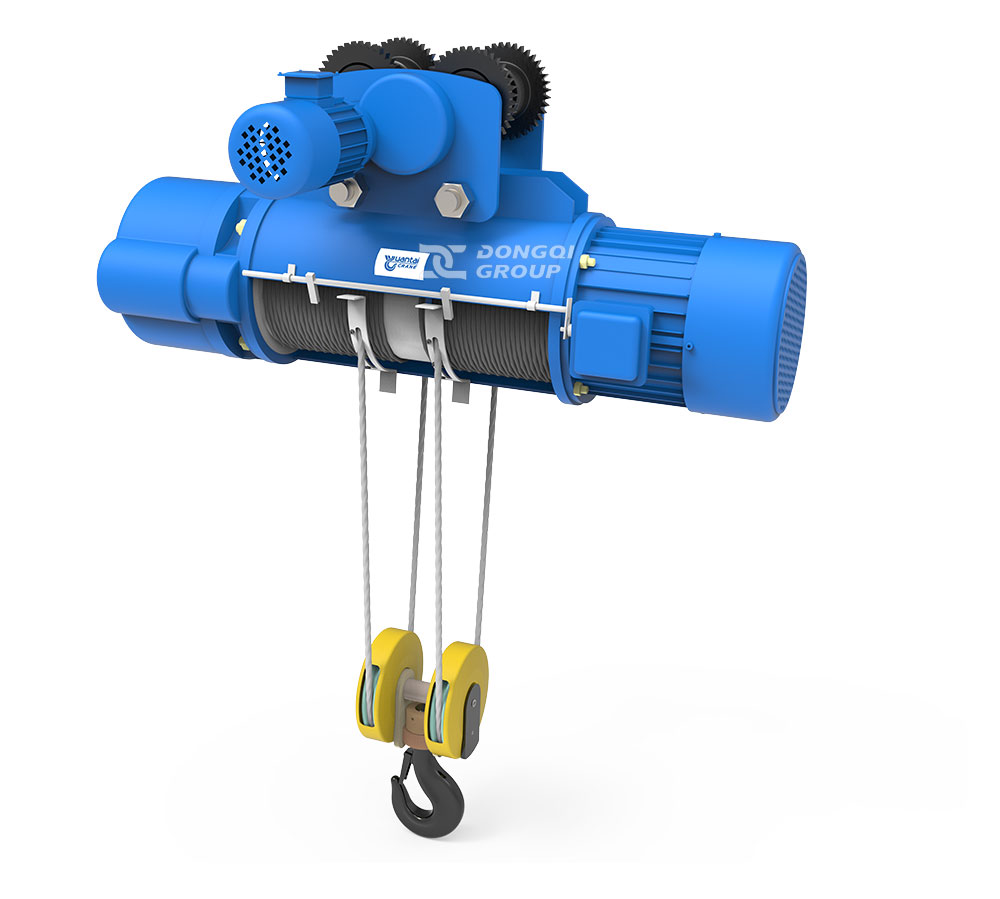

The CD1 and MD type steel wire rope electric hoists belong to a type of light and small lifting equipment. Commonly used tonnage includes 0.25, 0.5, 1, 2, 3, 5, 10, 16, 20 tons (t), etc. It can be installed on hoist single beams, bridge cranes, gantry cranes, and jib cranes. With slight modifications, it can also be used as a winch. Therefore, it is one of the commonly used lifting equipment in factories, mines, ports, warehouses, freight yards, shops, and other areas, and is an essential machinery for improving labor efficiency and working conditions. The lifting speed of the CD1 electric hoist is constant speed, and the lifting speed is single speed, which can meet general usage requirements. The MD1 electric hoist has two types of lifting speeds – normal speed and slow speed. When working at a slow speed, it can meet the requirements of precision loading and unloading, sand box clamping, machine tool maintenance, and other fine operations. Therefore, the use range of MD1 electric hoist is more extensive than that of CD1 electric hoist.

The design forms of CD1 and MD1 steel wire rope electric hoists include trolley running, trolley seat, trolley hanging, fixed seat, fixed hanging, etc. The manufacturer also provides design and manufacturing, installation and debugging, overhaul and renovation, repair and maintenance, annual inspection and maintenance services for non-standard lifting stars, lifting height, lifting/operating speed, and change of control methods, as well as more explosion-proof/mining/marine electric hoists, metallurgical high-temperature resistance, acid washing, frequency conversion speed regulation, etc Please consult customer service for the brand, technical parameters, drawing design, construction plan, and quotation budget of national/non-standard/specialized electric hoist manufacturers such as high winch, twin (child mother type), European new low clearance, coaxial synchronization, etc.

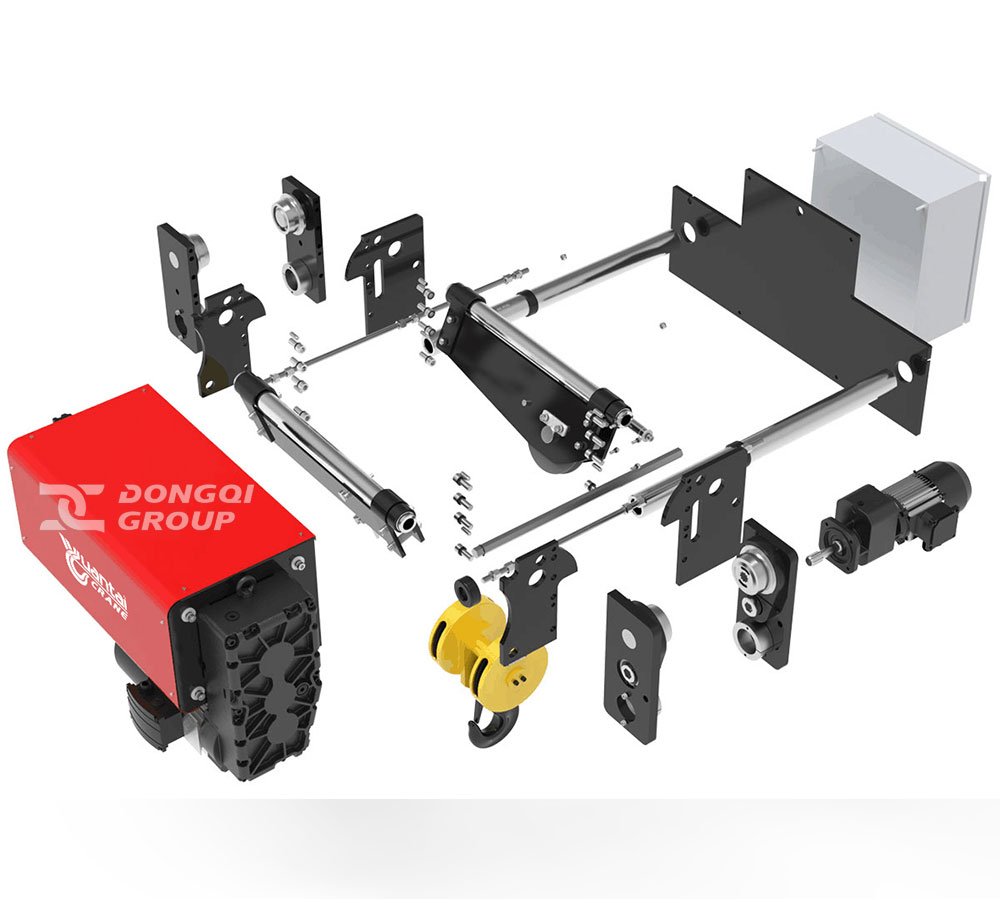

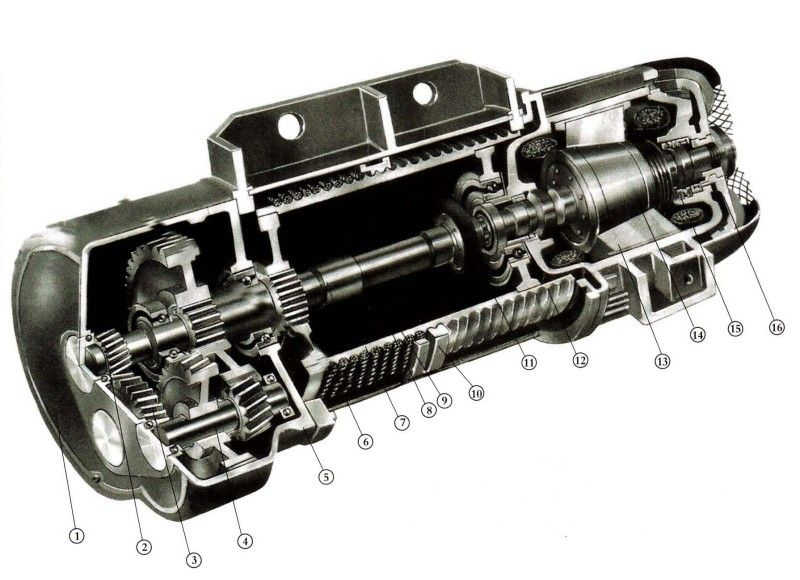

Anatomical diagram of CD1/MD1 electric hoist

1. Box cover, 2. First shaft, 3. Second shaft, 4. Third shaft, 5. Box, 6. Hollow shaft, 7. Rigid coupling, 8. Intermediate shaft, 9. Steel wire rope, 10. Rope guide, 11. Elastic coupling, 12. Reel, 13. Stator, 14. Rotor, 15. Pressure spring, 16. Brake (Wind blade brake wheel)

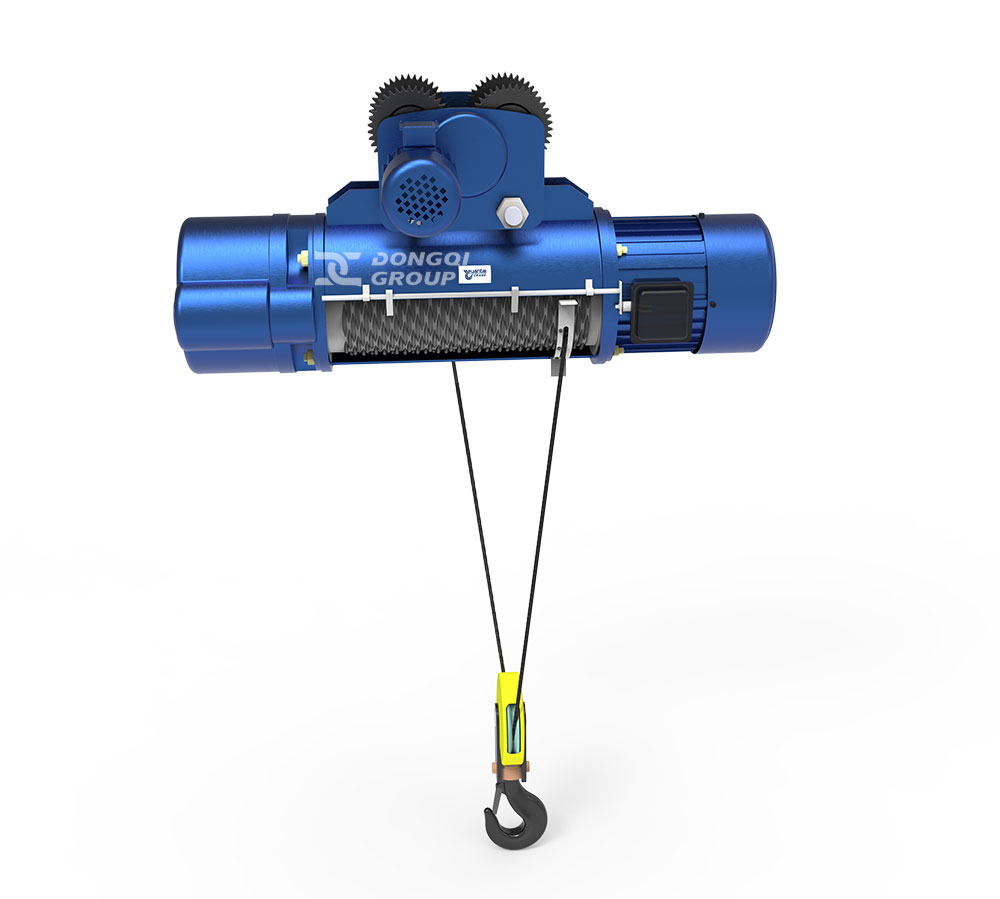

CD1 Wire Rope Electric Hoist Under 5 Ton

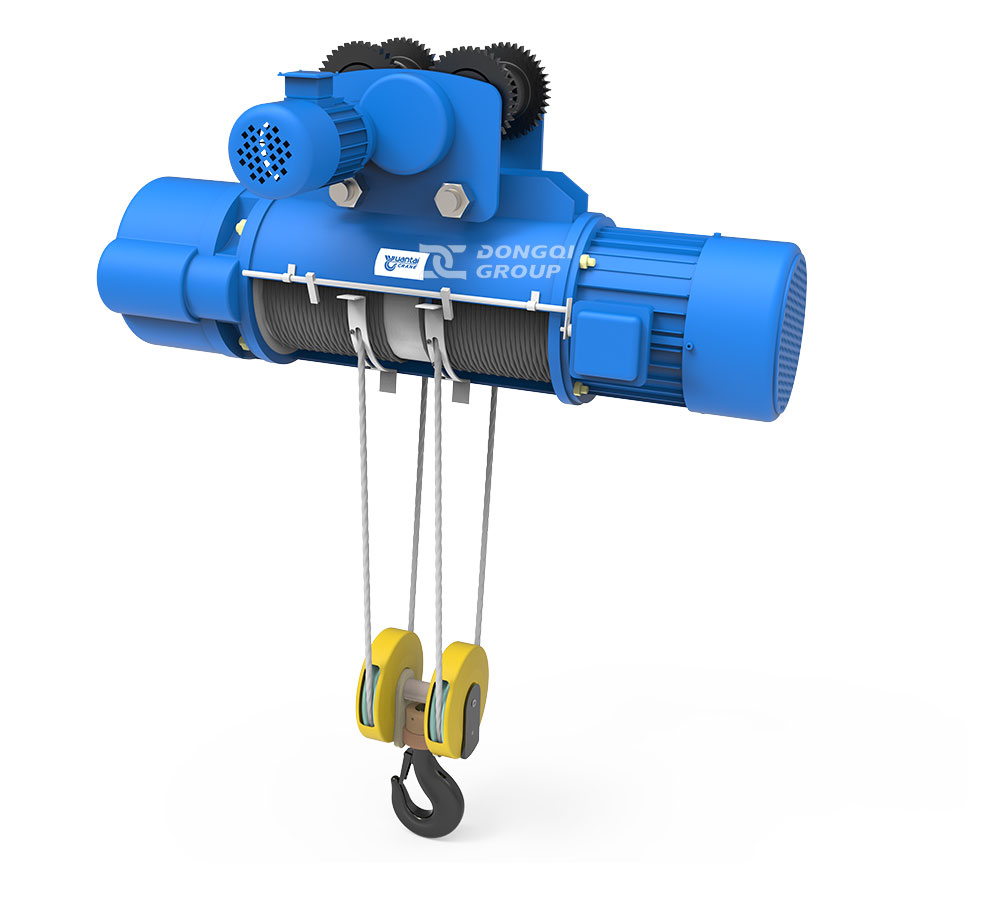

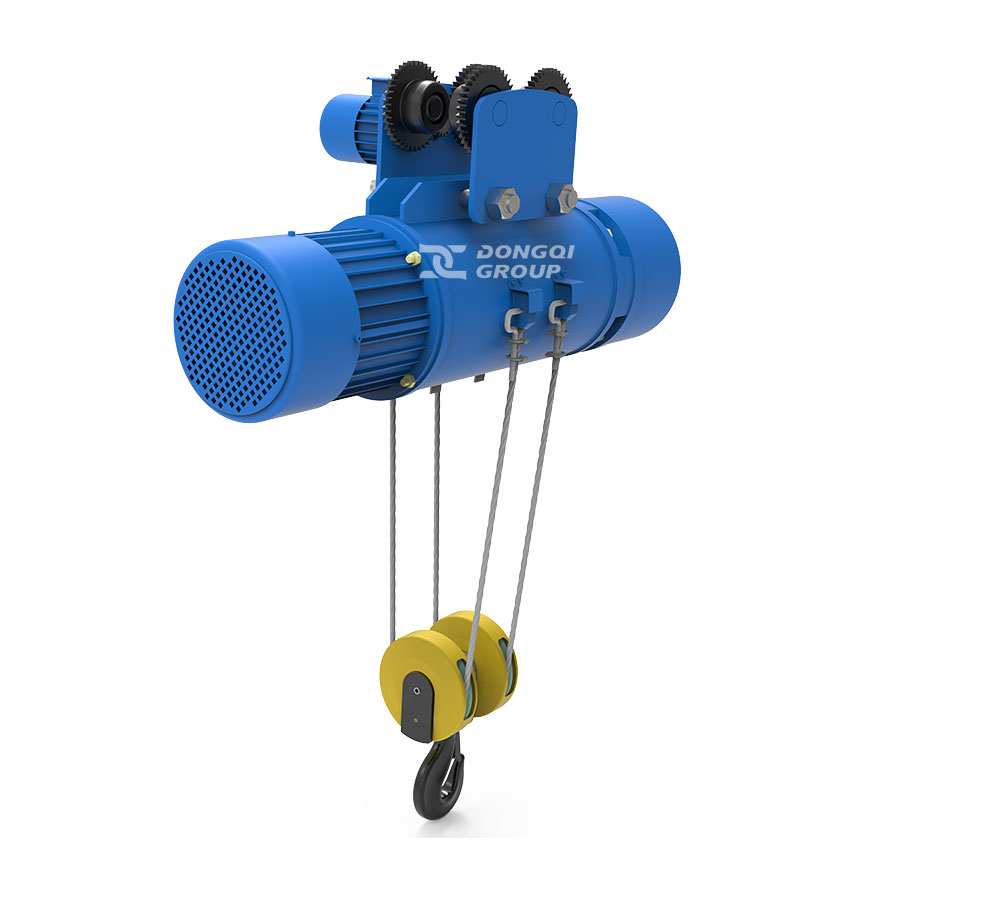

CD1 Wire Rope Electric Hoist Over 5 Ton

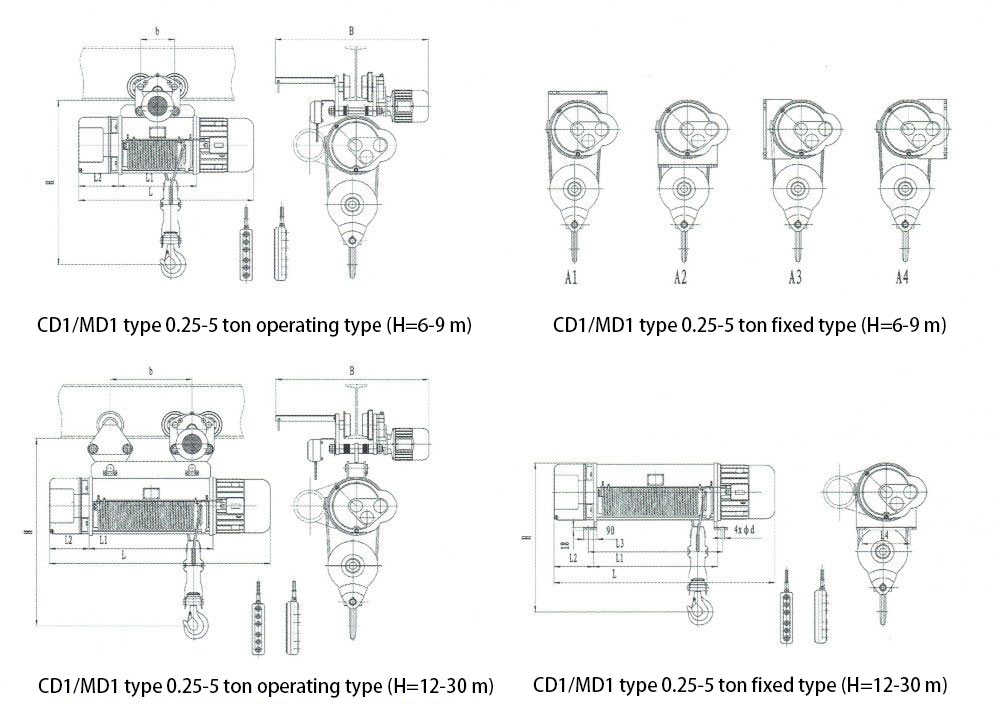

Outline dimension diagram of CD1/MD1 type 0.25-5 ton electric hoist

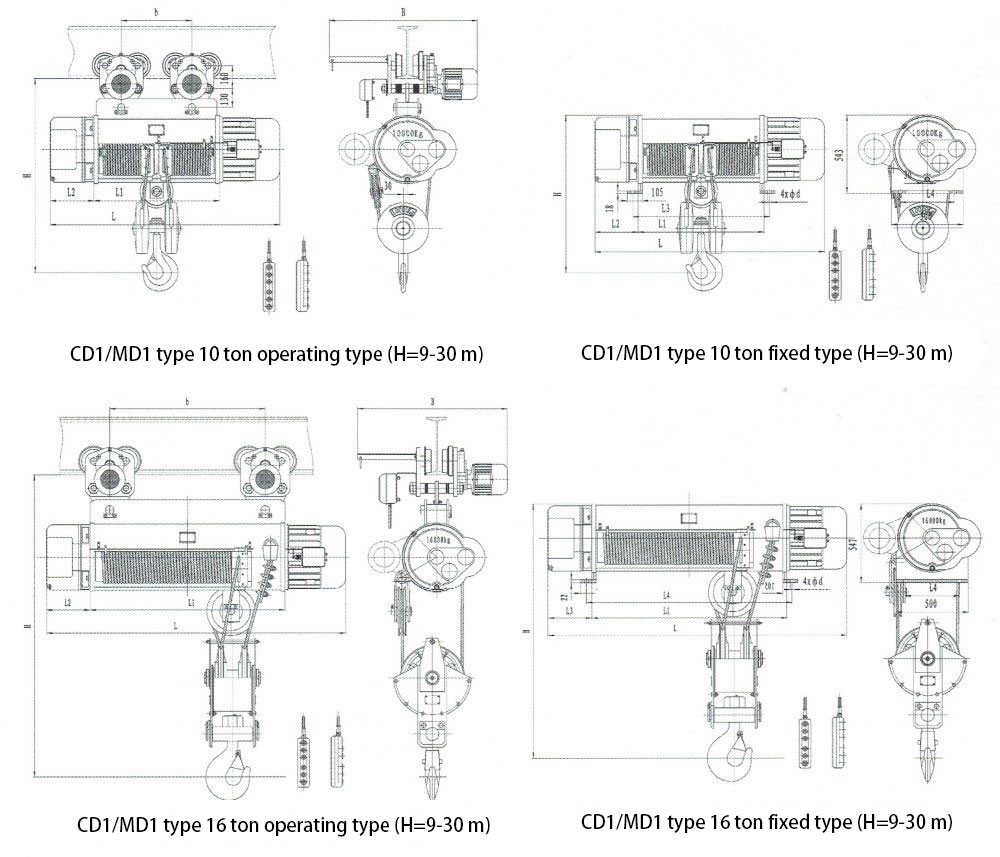

Outline dimension diagram of CD1/MD1 type 10-16 ton electric hoist