25-Sep-2023

QB Double Girder Explosion-proof Overhead Crane Uzbekistan

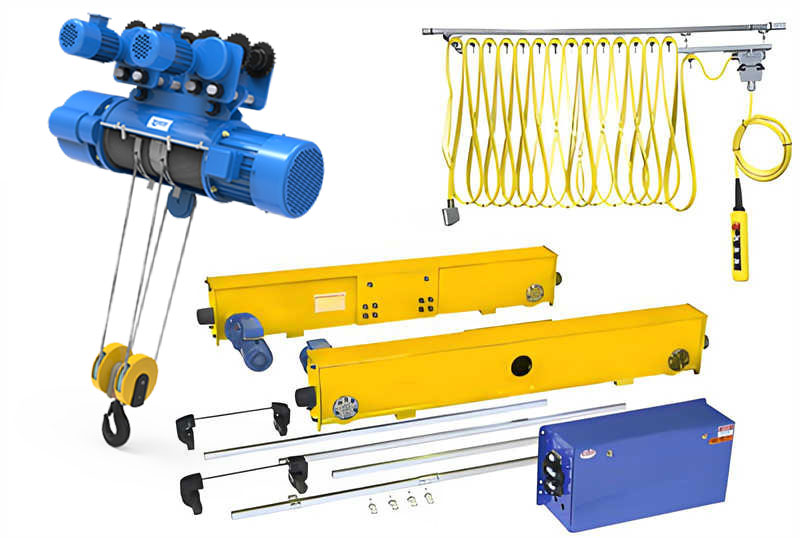

Dongqi Crane can provide QB explosion-proof cranes for customers in Uzbekistan. QB explosion-proof crane is a lifting equipment specifically used for material handling in flammable and explosive environments. It mainly consists of explosion-proof electric hoists, explosion-proof metal structures, explosion-proof components, and explosion-proof transmission devices. The QB explosion-proof crane is manufactured according to international advanced standards and has high explosion-proof performance. It can effectively prevent explosions caused by arcs, sparks, and overheating, providing safety assurance for material handling in flammable and explosive environments. During the manufacturing process, the QB explosion-proof crane adopts strict process control to ensure stable and reliable mechanical and safety performance. Due to its strong explosion-proof performance and stable structure, operators working in flammable and explosive environments can receive sufficient safety protection.

Basic Parameters

- Type: QB

- Lifting capacity: 5-50

- Span: 10.5-31.5m

- Working class: A4, A5Ambient

- Temperature: -20~40℃

Mainly consists of bridge structure, crane travelling mechanism, electric equipment etc.

All motors of QB type explosion-proof overhead cranes which electrical explosion-proof performance is in line with GB3836.2-2000 “for explosive gas atmospheres with explosion-proof electrical equipment-Part 2: Flameproof “d”,and the whole performance is in line with provisions of the standards of explosion-proof bridge cranes JB/T5897-1991.

The proof marks are Exd Ⅱ BT4 and Exd Ⅱ CT4.

Applied to explosion transfer capacity no higher than the II B or II C-class and the sites with explosive air mixture formed with inflammable gas (or steam) and air whose factory ignition temperature groups of not less than the T4 group.

The applicable hazardous area: 1 division or 2 division (refer to GB3836.1-2000).

This product is generally the ground controlling and also be cab operating according to user needs.

Working level: intermediate.

Features

(1) In General

The machine: Novel structure, attractive appearance and good technics;

Operation: Flexible and smooth, safe and reliable.

(2) Main Body

Double girder, welding box beam, camber meet national standard;

Adopt high quality carbon steel, Q235B or Q345B;

Main and end girder connected through level 10.9 high-strength bolt

Crane drive: IP54 or IP55, level F insulation

Efficiency brake, long life

(3) Electric System

Security trolley line or angle steel trolley line

The power supply of Travelling trolley adopt flat cable

Smoothly sliding, overall nice

(4) Protection Devices

For outdoor crane, should equipped with hoist mechanism, electrical box and rain cover of driving mechanism.

Install collision prevention device and sound & light alarm device.

(5) Controlling Ways

Generally, ground controlling.

Cab controlling is also available according to customer’s requirement, working system is intermediate.

Operating cab: open style and close style, left or right installation

Direction of entrance: side, end and top.

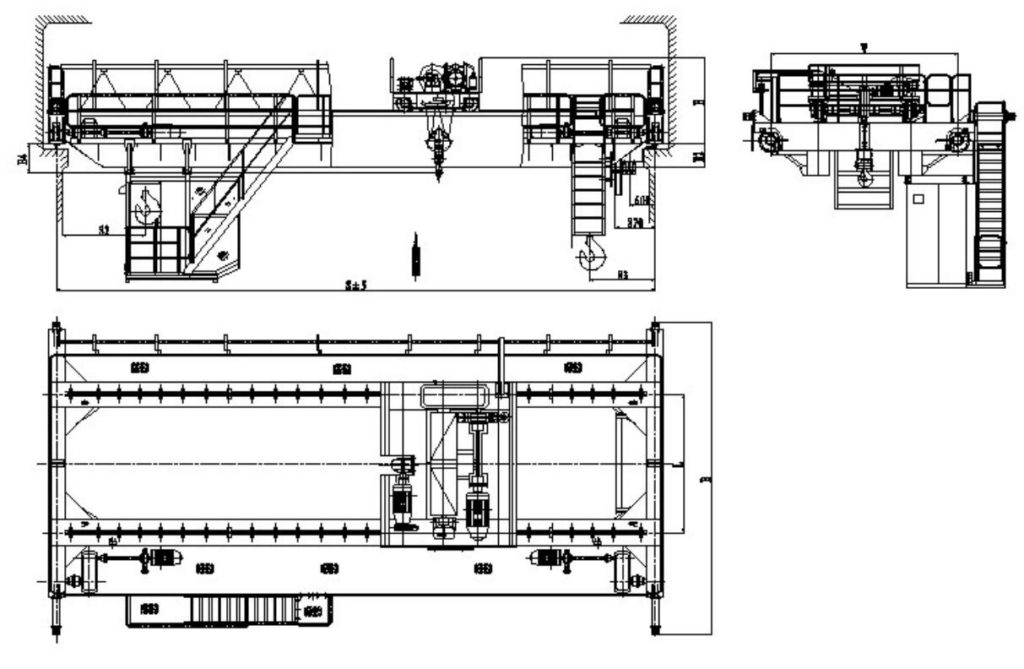

Design Drawings